We recently sent roughly 20 of our team members to LCI’s 2019 Congress, which was held in Fort Worth during the week of October 14. We asked five of them—an executive, a project manager, a senior and an assistant superintendent, and a non-operations person—to share their perspectives or biggest take-aways:

Nathan Wilke | Project Manager

One of the great things about attending Congress is being around so many like-minded people who share in the belief that there is a better way to build, and that it is achievable through Lean. It’s always good to know you’re not alone.

This was the largest Congress to date, and it’s wonderful to have so many people embracing Lean concepts and sharing ideas. One of the best things about Lean is the culture of idea-sharing; it’s so important to create an environment where people feel free to express their ideas, because you never know where the next best one will come from.

However, as one keynote mentioned, in order to maintain a competitive advantage, we can’t risk complacency. Companies and people must evolve and change—or get left behind. Don’t think that success today guarantees success tomorrow. Explore new ideas to maintain your competitive advantage and, in doing so, you will push Lean concepts further than you thought possible.

Finally, we must motivate the next generation of builders. I thought I understood some of the challenges we faced in our industry, but this Congress has completely opened my eyes. I want to build a long and fruitful career in this industry, but without enough people to satisfy the demand and join in the work, we have real problem on our hands. Therefore, we have a duty to nurture our next generation and share with them our passion and the rewards that can be found in this beautiful industry of ours.

. . .

Keyan Zandy | COO

I attended my first Lean Congress in 2007, and I’ve been hooked ever since. I look forward to going every year because I know I will come back energized with new ideas, a fresh perspective, and with opportunities to share and learn.

This year was extremely meaningful to me for two reasons. First, Skiles Group was there in full force as one of only 15 companies who sent more than 15 employees. As a firm who’s made Lean part of our culture, is was great for me to see so many of us being inspired to find new ways to think differently about our jobs and how we can work smarter. Second was the launch of the book I co-wrote with an old colleague, Joe Donarumo, called The Lean Builder. LCI has been extremely gracious in supporting and promoting our project, and I am so grateful that they saw fit to distribute it to all the Congress’ attendees. This is meaningful for me because I deeply believe in order to better our industry, we must share best practices to better the whole. I’m proud to have contributed to the community that has given me so much.

The biggest take-away for me this year came from Victor Sanvido, with Southland Industries. While accepting the LCI 2019 Pioneer Award, he reminded us that if we don’t enable our tradespeople, nothing will get done. This is the truth. We must give the men and women in the field the focus and attention they deserve, as they are the ones who truly bring the most value to the work.

. . .

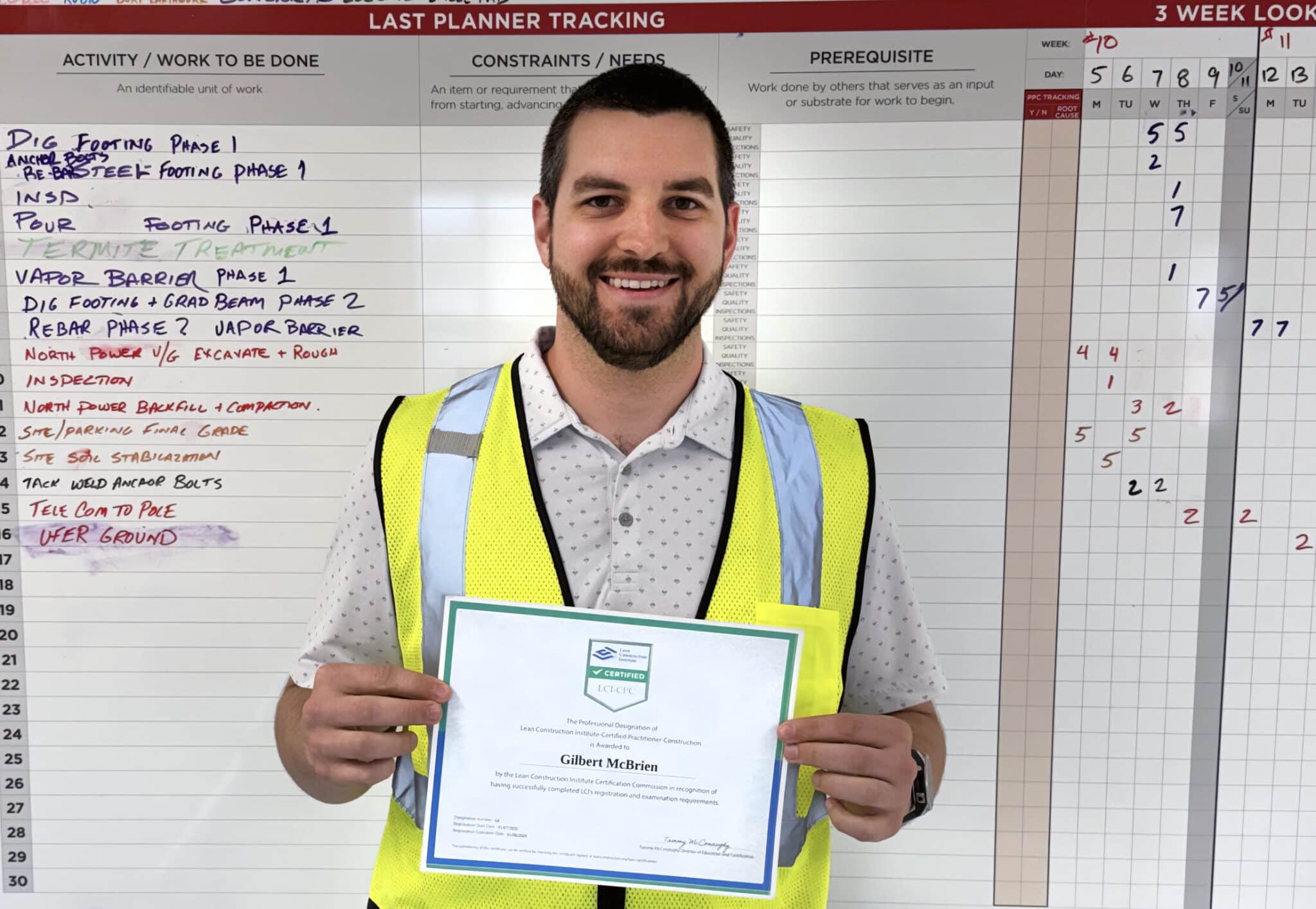

Benjamin Carter, CM Lean | Assistant Superintendent

As I walked away from LCI this year, I saw Lean with a new perspective, in a more personal way, and through a new lens.

Lean principles are built on the golden rule, “do unto others as you would have them do unto you.” This mindset is what builds a true foundation of Lean, both internally in your organization as well as externally into the industry. If you are going to build a culture of Lean, you must change behaviors first. The golden rule sets the standards of change from a traditional hierarchy to a top down approach. Empowering the individual, where the value is created (i.e. the worker who puts the work in place) is the essential element to building the structure of any Lean framework.

It is up to each and every one of us to cultivate the transformation of new industry standards utilizing Lean principles. No processes, best practices, or tools will enable the last planner to be effective and efficient until we respect one another through the golden rule. High power teams reap the benefits of this philosophy time and time again as they sow their seeds of individual empowerment.

. . .

Dara Davulcu | Director of Marketing

My biggest take-away from Congress is not tool- or process-oriented; it’s cultural. I was struck by the fact that every session I attended, regardless of topic, incorporated interpersonal aspects: creating trust, providing everyone with a voice, building healthy teams, sharing ideas, establishing psychological safety, fostering equity, embracing diversity (gender, race, and discipline), promoting personal or professional growth, and highlighting transparency, honesty, and accountability. These were common threads woven throughout the content in every room I walked into.

Everything about Lean is ultimately about the human beings doing the work, and given how much we, in every industry, are becoming reliant upon technologies and pushing ourselves to work faster &/or cheaper, I came to deeply appreciate how much emphasis the Lean Construction community places on PEOPLE: respecting them and striving to make their projects and workplaces healthy, progressive, and effective.

. . .

Buddy Brumley | Senior Superintendent

These events recharge me and validate for me all of the work that we are doing at Skiles Group on our Lean journey. Here are my take-aways from 2019:

- Keep working and improving your system, using your Lean tools, and tracking each job’s successes and failures.

- Don’t bash the teams that struggle with Lean; encourage them to learn from their mistakes and improve for the next time out.

- Lean is hard at the start of the job, but easy at the end because the system is working. The old way is easier at the start and harder at the end, due to the lack of proper flow.

- Change the way you lead before you have to—usually, it’s too late by then.

- A few things done well is better than a lot of things done averagely.